Getting the most lifespan out of your cutting tools is crucial for any manufacturer. While new tools are always tempting, strategically utilizing used ones can save you money and still deliver outstanding results. Evaluating your tools regularly for wear and tear is the first step. Look for signs like chipping, cracks, or discoloration. With proper

End Mill Selection Guide for Optimal Machining Performance Choosing the Right End Mill for Success

Selecting the ideal end mill is essential for achieving optimal machining performance. A wide range of end mills with diverse geometries, materials, and coatings are available, each designed to excel in specific applications. Factors such as workpiece material, desired finish, cutting speed, and feed rate must be carefully considered when making yo

Used Cutting Tools: Value, Quality, and Inspection

When inspecting used cutting tools, it's crucial to weigh both their potential value and their current quality. A well-maintained tool can offer significant cost savings compared to purchasing new, but its performance is directly tied to its condition. Careful examination is essential to identify signs of wear, damage, or improper use that could af

Refining End Mill Tool Holders for Enhanced Machining Precision

Precision machining requires the utmost attention to detail at every stage. Among the crucial factors influencing precision is the tool holder itself, which serves as the intermediary between the cutting tool and the machine spindle. A well-optimized end mill tool holder can significantly enhance machining precision by minimizing vibration, reducin

Refining End Mill Tool Holders for Enhanced Machining Precision

Precision machining demands the utmost attention to detail at every stage. Among the crucial factors influencing quality is the tool holder itself, which serves as the intermediary between the cutting tool and the machine spindle. A well-optimized end mill tool holder can significantly improve machining precision by minimizing vibration, reducing t

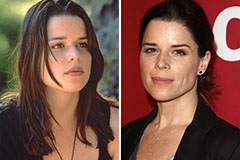

Neve Campbell Then & Now!

Neve Campbell Then & Now! Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Andrew McCarthy Then & Now!

Andrew McCarthy Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!